3D Modeling Layer by Layer: A Glue It Together Introduction to 3D Printing

3D printing has opened a cool new frontier of custom manufacturing that brings freedom to individuals interested in design, invention, or just in need of a rare or unusual part. With a hands-on modeling and design project using Autodesk 123D Make, students can design and assemble a layered 3D model for a better understanding of how 3D printing and additive manufacturing works.

3D printing is all the buzz. From replacement parts for household objects or toys that are broken to one-of-a-kind creations to a large-scale approach to manufacturing that may revolutionize the way products are made, 3D printing has changed how people think about "making" things that once required industrial machines and molds. In addition to giving individual inventors and designers new options for testing out ideas, 3D printing brings new possibility to many big industries, from automotive to healthcare. 3D printing is a game changer, and industry and DIY and maker communities alike are excited by what 3D print technologies enable, but the printer in your school computer lab or home office probably still prints out the same flat images and text as it always did.

What is 3D printing all about? What does it really mean for a printer to "print" a ready-made, fully-functional object, on demand, similar to the way you might request an item from a vending machine?

One-of-a-kind Designs

You may have read stories about "printed" objects ranging from artificial organs to cell phone accessories and other tchotchkes, things that someone wants to make but doesn't need a million of or even a hundred. Or maybe what you need is a specific little piece to replace something that is broken, a piece that is hard to find or no longer made. With 3D printing, you can make just one of any item you can imagine—as long as you can create a digital 3D model. There are no expensive molds and machines that have to be made, customized, or altered to handle each design or each change. Instead, using a digital design file as a blueprint, a 3D printer prints out the object, layer by layer.

With 3D printing, the z axis comes into play as the printer adds "depth" to the print. In order to create a file for 3D printing, designers use computer-aided software to create a 3D model of an object that can then be printed with a special 3D printer. Depending on the printer, 3D printed objects can be made from a variety of materials, including rubber, plastics, paper, and even metals. Using the digital blueprint, the printer (loaded with the chosen material) extrudes the material layer upon layer, similar to the way that a regular printer deposits ink as the printer head moves back and forth across the page—only dimensionally instead of just in flat, horizontal rows.

Creating Paper Models

The layer by layer approach central to 3D printing is an example of additive manufacturing. In traditional manufacturing, an object might be created by taking a block of material and removing (or subtracting) material to get to the desired shape. Sculpting something out of a block of soap or a block of wood, for example, involves a subtractive approach—you whittle away what you don't need to leave only the desired shape behind. With additive manufacturing, layers of material are added, one by one, to build the object to the desired shape and size. Only what is needed is used, so there is less waste.

That virtually any object imaginable, including artificial organs, can be constructed by printing "layers," may seem hard to believe. A novel software application from Autodesk helps remove the mystery of additive construction by giving users a hands-on way to create their own additive models.

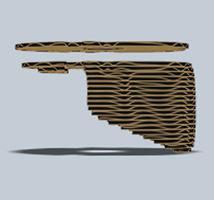

Autodesk's 123D Make auto-converts 3D digital objects into 2D vector-cut patterns or templates. Using 123D Make, students can print out the individual layers needed to construct a 3D model (designed in another program) and then glue or tape the layers together to manually build the 3D object. Using paper (or cardboard) to construct a 3D object from layers lets students see, from the ground up, how a 3D printer creates a 3D object from layers. It's a great creative exercise, but using 123D Make is also a great way to take a hands-on, nuts-and-bolts look at how an object can be built from layers—and how computer-aided design and modeling is related to what a 3D printer will "do" when printing out the dimensional object.

Making a 3D Model

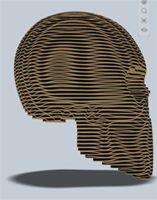

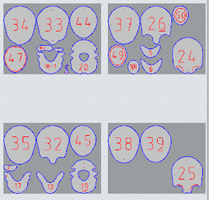

Using 123D Make, students can explore fundamental principles of 3D additive design by making their own 3D object from layers. Opening up one of the many gallery examples is a great way to get started. Choose a model like a "skull," "rocket," or "rhino," and you can immediately see how layers are used to create the item. With 123D Make, students can change the size of the item, change the direction of the "slices" (which plane is used for slicing?), and even view the same object as it could be assembled using various techniques, including stacking (layering) and paper folding.

Once a design has been finalized, it can be laser-cut (professionally) or, for an at-home look at the process, the design can be printed out on multiple sheets that contain all of the slices necessary to make the object, layer by layer. Trace and cut the shapes from cardboard, grab some glue, and you have the makings of a fascinating creative engineering activity. (Some versions of the 123D Make application animate the assembly steps, layer by layer, as shown in the screenshot below. All layers are numbered for DIY assembly.)

123D Make is available as an iOS or Android app, a standalone software product, and a web application.

Next Steps

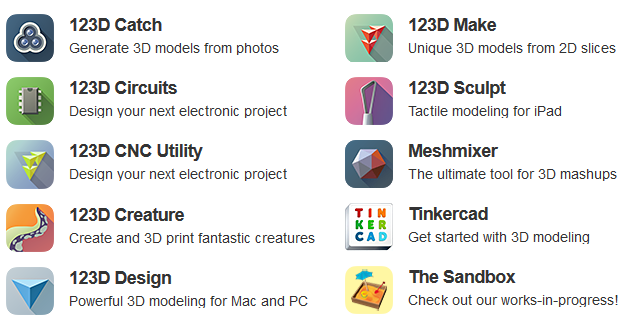

After experimenting with a cardboard-based, glue-it-together 3D model, students can continue to explore 3D modeling and 3D printing using one of a range of Autodesk tools. The Autodesk 123D site connects students with a number of free apps and tools, resources, and samples to help jump start exploration of 3D and computer-aided design.

Premier Design Tools for Educational Use

Autodesk gives students, educators, and educational institutions free access to professional design software, creativity apps, and real-world projects. For more information, details about education use, and to download software, visit the Autodesk Education Community.

What Will You Make?

If you are already a user of Autodesk software, we would love to hear from you! If you try 123D Make, or any other tool on the 123D site, please let us know. We would love to see what you build, design, explore, or even print!

Categories:

You Might Also Enjoy These Related Posts:

- Plastics and Earth Day - Science Projects

- Arduino Science Projects and Physical Computing

- 10+ Robotics Projects with the BlueBot Kit

- 5 STEM Activities with Marshmallow Peeps

- March Madness Basketball Science Projects: Sports Science Experiments

- Women in STEM! More than 60 Scientists and Engineers for Women's History Month

- Explore Artificial Intelligence and Machine Learning with Student AI Projects

- 10 Reasons to Do the Rubber Band Car Engineering Challenge