Abstract

Amaze your friends and family by moving water with just a few turns of your wrist! Nope, it's not a magic trick. It's simply an Archimedes screw. In this science project, you will build a very simple pump, called an Archimedes screw, to transfer water from a low-lying location to a higher location.Summary

Michelle Maranowski, PhD, Science Buddies

This project is based on a design for a homemade Archimedes screw from this website:

de Campos Valadares, E. (2005, September 23). Fun Physics Experiments with Household Objects: Hand-Operated Water Pump (Archimedes' Screw). Retrieved April 9, 2008.

Objective

For this science project you will build an efficient Archimedes screw pump, using commonly found materials.

Introduction

Archimedes of Syracuse was born in the 3rd century BC. He was one of the most important inventors of his time because he liked to solve problems; particularly problems that would help his Italian hometown prosper. During the Siege of Syracuse, Archimedes developed the Archimedes heat ray, which used parabolic mirrors to focus the energy of the sun onto incoming enemy ships, and supposedly caught them on fire. For many years, several modern-day scientists didn't believe this kind of weapon could have been built. However, recently a group of students at MIT showed that an Archimedes heat ray weapon is possible. Although, they do not claim that the story is completely true.

Image Credit: Eon Images / Public domain

Image Credit: Eon Images / Public domain

Figure 1. Engraving of Archimedes of Syracuse. (eonimages.com, 2007.)

The King of Syracuse requested that Archimedes build the biggest luxury ship possible. This ship proved to be leaky and Archimedes had to design a device to rid the hull of bilge water. So he designed the Archimedes screw. The screw was very effective because it got rid of the water and only required one person to operate it. The Archimedes screw was also used to transport water from low-lying areas up to irrigation ditches. The design is so effective that it is still being used in many modern-day applications. For instance, it is used to lift wastewater in treatment plants and even to lift water at the Shipwreck Rapids water ride at Sea World in San Diego, California. It's a tool that has never gone out of style.

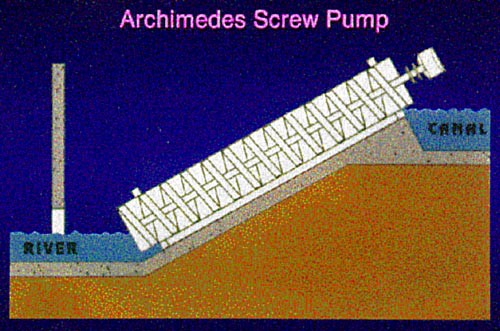

The Archimedes screw is a positive-displacement pump. A positive-displacement pump traps an amount of fluid from a source and then forces the fluid to move to a discharge location. The Archimedes screw is made up of a hollow cylinder and a cylindrical core. The core sits inside of the hollow cylinder. Helical blades are wound around the core and are secured tightly against the hollow cylinder. The helical blades create pockets between the core and the inner wall of the hollow cylinder. To use this device as a pump, one end is placed in a low-lying fluid source and then tilted up into a discharge tank. To move water, simply rotate the screw. As the screw moves, it scoops up a small amount of water into the first pocket. On the next turn of the screw, the first pocket of water moves to the second pocket, and a new scoop of water enters the first pocket. This motion continues until finally the first scoop of water comes out at the other end.

Image Credit: U.S. Department of the Interior, Bureau of Reclamation / Public domain

Image Credit: U.S. Department of the Interior, Bureau of Reclamation / Public domain

Figure 2. Here is an inside view of an Archimedes screw pump. The screw is turned and water is scooped up from the river and makes its way up the screw pockets to the canal. (U.S. Department of the Interior, 2004.)

The site of the fluid to be moved and the amount of fluid to be moved determine the outer radius of the Archimedes screw (the distance from the center of the core to the outer wall of the hollow cylinder), the length of the tool, and how much the tool has to be tilted (the slope). But there are other parameters that are utilized to optimize the efficiency of the screw; for instance, the inner radius (the distance from the center of the core to the inner wall of the hollow cylinder), the number of blades, and the pitch of the blades (Rorres, 2000). The pitch or period is the length of one cycle of the blade.

In this science project, step into Archimedes' shoes. Design the most-efficient pump using the materials listed in the Materials and Equipment list below. Have fun and remember that Archimedes loved solving difficult problems!

Terms and Concepts

- Archimedes of Syracuse

- Archimedes screw

- Pump

- Radius

- Slope

- Pitch

- Period

Questions

- What other inventions did Archimedes develop?

- What areas of science did Archimedes study?

- What are some modern uses of the Archimedes screw?

- Can you explain how an Archimedes screw works?

Bibliography

- U.S. Department of the Interior. (2004, October 26). Reclamation History. Retrieved March 9, 2016.

To learn more about Archimedes and his contributions, check out the following websites:

- Rorres, C. (n.d.). Archimedes. Retrieved April 7, 2008.

- Wikipedia Contributors. (2008). Archimedes. Wikipedia: The Free Encyclopedia. Retrieved September 13, 2012.

Check out this site for information about the Archimedes screw, as well as an animation of how it works:

- Wikipedia Contributors. (2008). Archimedes Screw. Wikipedia: The Free Encyclopedia. Retrieved April 9, 2008.

- Rorres, C. (2000). The Turn of the Screw: Optimal Design of an Archimedes Screw . Journal of Hydraulic Engineering, Vol. 126, No. 1, 72-80. Retrieved September 13, 2012.

Materials and Equipment

- PVC pipe, ½-inch inner diameter, 2-foot length; available at hardware stores

- Clear vinyl tubing, 10-foot length, with a 3/8-inch outer diameter x ¼-inch inner diameter; available at hardware stores

- Clear vinyl tubing, 10-foot length, with a 3/4-inch outer diameter x ½-inch inner diameter; available at hardware stores

- Strong and sticky tape, such as Gorilla tape or duct tape

- Permanent marker

- Retractable blade knife or strong scissors

- Lab notebook

- Liquid measuring cup

- Spoon

- Water

- Food coloring

- Bowls, 12-oz (2); plastic, glass, or ceramic all work fine

- Tape (Scotch® tape works fine)

- Pen

- Books of various thickness or pieces of plywood board; available at hardware stores (1-2)

- Helper

- Graph paper or an online graphing program like Create a Graph

Experimental Procedure

Making Your Archimedes Screw

- Using the PVC pipe and the ¼-inch-inner-diameter vinyl tubing, take a piece of strong tape and tape one end of the tubing to the outside of one end of the pipe such that a ¼-inch length of tubing is hanging off the end.

- Carefully wrap the tubing around the pipe in regular intervals until you come to the other end of the pipe. From that point, add a ¼ inch and mark that spot on the vinyl tubing with a permanent marker.

- Unwrap the tubing and cut it with scissors or a knife at the mark. Ask an adult for assistance.

- Rewrap the cut piece of tubing around the pipe in regular intervals and tape it down with pieces of strong tape along the pipe. There should be a ¼-inch of tubing hanging off both ends of the pipe, past the sections that you taped down. The starting section will reach into the water, allowing it to travel through the tube and the end section will help get the water out. By wrapping the tubing in regular intervals you are establishing the period of the tubing.

- Count the number of times you have wrapped the tubing around the PVC pipe. Divide 2 feet (the length of the PVC pipe) by the number of times you wrapped the tubing around the PVC pipe. This value is the period and is in units of feet. Note this down in your lab notebook in a data table similar to the one shown at the bottom of the Experimental Procedure.

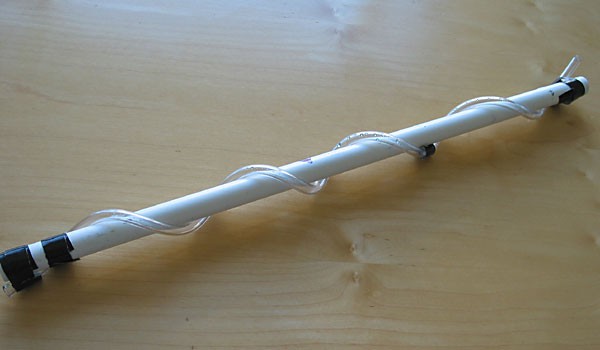

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Figure 3. Experimental Archimedes screw.

Setting Up Your Bowls

- In your liquid measuring cup, mix a few drops of food coloring in 1 cup of water. This makes the water easier to see.

- Now make tape loops with the Scotch tape to stick to the bottom of one of the Styrofoam bowls and press the bowl onto a table so it stays in place.

- Pour a ½ cup of the colored water into the other Styrofoam bowl. With a pen, mark the level of the water on the bowl. Pour the water back into the measuring cup.

- Making more tape loops, carefully tape the marked bowl onto one of the books or plywood boards so that it will stay in place during the experiment. This bowl is the discharge bowl.

Testing Your Experimental Setup

- Now you are ready to test your experimental setup and determine what slope works best so you can run your trials. Place the marked bowl on the book or plywood about 2 feet away from the bowl taped to the table. Pour the 1 cup of water into the bowl on the table.

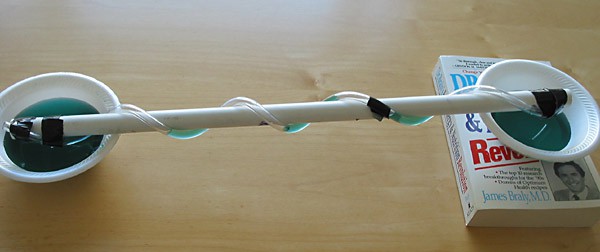

- Place your Archimedes screw across the two bowls, as shown in Figure 4. Be sure the extra ¼ inch of tubing hanging off the end is in the bowl of water on the table. Turn the screw so that every time the end of the tube goes into the water it scoops up some of the water.

- Tilt the screw so that one end is in the water and the other end is in or close to the bowl that you want to move the water to, which in this case, is the bowl taped to the book or plywood.

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Figure 4. Experimental setup.

- Make sure that as you turn the screw, the water doesn't fall back out of the screw. If the water does fall out, adjust the tilt of the screw, the placement of the bowls, and/or the height of the discharge bowl. Use an extra book or board if needed.

- Turn the screw a few times to make sure that the water is traveling through the tubing. Experiment with how fast you can turn the screw and still move water through the tube. Going too fast might not lead to positive results.

Running Your Trials

- Now you're ready to start running your trials. Hold the screw vertically and empty all of the water from the tubing and the discharge bowl back into the bowl on the table.

- Using your permanent marker, make a mark on the middle of the pipe at the position when the vinyl tubing is just about to enter the water. This will help you keep track of the number of turns you make. Turn the pipe so the mark is facing up, and then start turning the screw until the mark is facing up again. You have made one turn and should see some water in the tubing. On each successive turn, the opening of the tubing should be completely under water so that you scoop as much as possible.

-

Continue turning the screw until a ½ cup of water is in the discharge bowl. Make sure that you maintain the same tilt the whole time you are turning the screw. Also make sure that you are scooping up water on every turn. Have your helper help you count the number of turns as you go along. You can gauge when you have about a ½ cup in the discharge bowl, based on the pen marking you made when you first started. To be exact, confirm that you have a ½ cup of water in the discharge bowl by pouring it into the measuring cup. One person should hold the screw in place and the other person should carefully remove the bowl from under the screw and measure the water.

- If the amount of water in the discharge bowl is not a ½ cup, continue turning the screw until you get a ½ cup.

- If the amount of water in the discharge bowl is greater than a ½ cup, empty all of the water back into the first bowl and restart this step.

- Keep track of the number of turns it takes to move a ½ cup of water from the starting bowl into the discharge bowl. Note this information in your lab notebook.

- Repeat "Running Your Trials" two more times. Every time that you start a new trial, empty all of the water back into the measuring cup. Make sure that you have a full cup of water at the start of each trial. If you do not, then add water into the measuring cup until you have 1 cup. For each trial, note the information in your lab notebook.

- Calculate the average of the results of the three different trials and record them in your data table.

- Now unwrap the ¼-inch-inner-diameter tubing from the pipe. Take the ½-inch-inner-diameter tubing and wrap that around the ½-inch-inner-diameter PVC pipe. Use the same period as you did for the ¼-inch tubing. Wrapping this tubing will be harder than it was with the ¼-inch tubing because the tubing is larger and stiffer. Have your helper assist you with wrapping. Repeat the entire experiment with the new Archimedes screw. Remember to record the data you collect in your lab notebook. See the FAQ for more tips if you have trouble wrapping the ½-inch-inner-diameter tubing.

- Plot your data. Label the x-axis Design and the y-axis the Average Number of Turns to Move a ½ Cup of Water. Which design is more effective at moving water? Why?

| Design | Period | Number of Turns to Move ½ Cup of Water |

|

|---|---|---|---|

| ¼-inch tubing wrapped on ½-inch pipe | Trial #1 | ||

| Trial #2 | |||

| Trial #3 | |||

| Average of all trials | |||

| ½-inch tubing wrapped on ½-inch pipe | Trial #1 | ||

| Trial #2 | |||

| Trial #3 | |||

| Average of all trials | |||

Troubleshooting

For troubleshooting tips, please read our FAQ: Moving Water with the Archimedes Screw Pump.

Ask an Expert

Global Connections

The United Nations Sustainable Development Goals (UNSDGs) are a blueprint to achieve a better and more sustainable future for all.

Variations

- Change the period of the tubing to increase or decrease the number of wrappings and investigate how this affects the number of turns it takes to move ½ cup of water from the bowl on the table to the discharge bowl.

- Change the diameter of the pipe. Try using a 2-foot-long, 1-inch-inner-diameter PVC pipe with the ¼-inch-inner-diameter vinyl tubing. Does it make a difference?

Frequently Asked Questions (FAQ)

Ask an Expert

Careers

If you like this project, you might enjoy exploring these related careers: