Summary

Michelle Maranowski, PhD, Science Buddies

If you want a Project Idea with full instructions, please pick one without an asterisk (*) at the end of the title.

Abstract

A ship is a busy place. When out to sea, naval, research, and fishing vessels pull or push heavy loads, like research equipment and crab pots, into and out of the water. But equipment and pots can weigh hundreds of pounds. So how does a ship's crew lift loads efficiently and accurately? With a hydraulic knuckle crane, of course. But what is hydraulics and why does hydraulics make certain tasks easier?Hydraulics is the study of liquids and their mechanical properties: how they move, resist movement, act when subject to pressure, and so forth. In engineering, one application of hydraulics is using liquids, like water and oil, to move things. Why use a liquid to move things, instead of, say, air? One important reason is that a liquid is incompressible, which means that if you press on it, you cannot change its volume. For example, if you have a cup filled with marshmallows, you can fit even more marshmallows into the cup by compressing (squeezing) the marshmallows together. But if the cup is filled with water, you cannot fit more water into the cup - no matter how hard you squeeze! Because liquid is incompressible, applying a force (for example, a push or a pull) to one end of a hydraulic system transmits (moves) the force through the liquid to the other end.

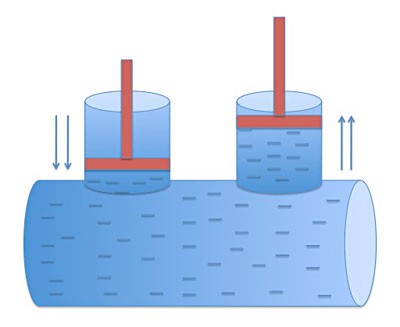

Pressure is a force spread out over an area, or a force divided by an area. Pushing on the top of a glass of water, for instance, puts pressure on all of the water in the glass. Another way of thinking about pressure is to imagine pushing on an object with your finger or with the palm of your hand. In both cases, you are applying the same force, but the pressure is different because the area of the tip of your finger is much smaller than the palm of your hand. Figure 1 shows a simple hydraulic system that uses the concepts of force and pressure.

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Figure 1. This simple hydraulic system has two pistons in cylinders on the top.

The hydraulic system in Figure 1 is made up of a liquid-filled tube topped with two pistons that move up or down as the liquid moves. Applying a downward force on this closed system (in this case, pushing down on the left-hand piston) causes the liquid to move against the right-hand piston and, because the liquid is incompressible, push the piston up. The pressure in the liquid is the same at every point within the liquid, because the liquid is incompressible. When the energy from the force applied to one piston is transferred to the liquid and then to the second piston, thus moving it, we say that work has been done by the first piston. Hydraulic machinery, like wheelchair lifts and excavators, use liquids to do work. That work can be applied to big jobs, like lifting heavy loads.

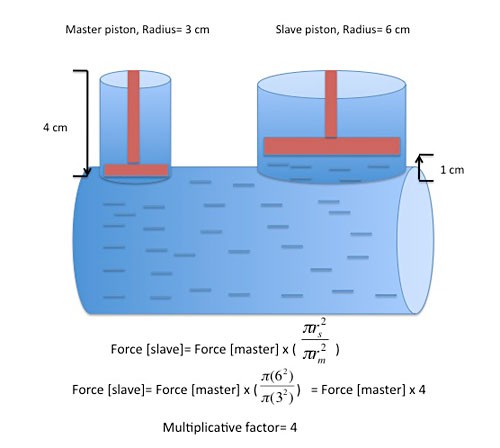

An advantage of hydraulic tools is the concept of force multiplication. Force multiplication enables the force you apply to one piston to be multiplied, by a multiplicative factor, to make a larger force acting on the second piston. This only works if the first piston is smaller in area than the second piston. Taking the simple hydraulic system mentioned and altering it to use force multiplication, it will look like Figure 2.

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Image Credit: Michelle Maranowski, Science Buddies / Science Buddies

Figure 2. Simple hydraulic system with pistons of different areas. The piston with the smaller area is called the master and the piston with the larger area is called the slave. The difference in areas between the two enables force multiplication.

When you push in the master (smaller) piston, the amount of force applied to the slave (larger) piston by the liquid is multiplied by the ratio of the area of the slave piston to the area of the master piston. Using Equations 1 to 3 derives this relationship.

Equation 1.

|

Because pressure is force acting over an area, Equation 1 is transformed into Equation 2.

Equation 2.

|

In Figure 2, the area of both pistons is a circle and the area of a circle is πr², where r is the radius of the circle. Using this given, you can transform Equation 2 into Equation 3 to find the force the liquid applies on the slave piston.

Equation 3.

|

The ratio of the areas of the two different pistons in Equation 3 is called the multiplicative factor. Using Equation 3, you can see that the force on the slave piston in Figure 2 is four times the force applied by the master piston. So if the master piston applies 1 N of force to the liquid, the liquid's force on the slave piston is 4 N. But note that the master must be pushed down 4 cm while the slave rises only 1 cm.

Force multiplication is the reason hydraulic machinery is so useful. A small force from the operator on one end of the machine is multiplied and results in a much larger force on the other end. Construction equipment like excavators and forklifts use the force multiplication of hydraulics. Often these machines have hydraulic cylinders. A hydraulic cylinder is made up of a piston and a cylinder that houses the piston and the hydraulic liquid.

In this mechanical engineering project, you will apply the principles of hydraulics to build a working model of a knuckle crane that will pick up and move a load. You can use syringes to act as the hydraulic cylinders. The plunger of the syringe acts as the piston in the hydraulic cylinder.

One approach to building your model knuckle crane is to use 4-inch bolts to attach two or three lengths of 2 x 2-inch wood. If you take this approach, you will have to figure out the best way to attach the pieces of wood together. You may want to attach syringes and pistons to each arm of the crane to make each part move separately from the other. You will also have to determine where to attach the syringes, as well as the sizes of syringes to use and how you will use force multiplication. Finally, you will need to choose the best attachment for picking up a load. Will you use a hook or a claw?

If you would like to see an example of hydraulics at work, take a look at this Science Buddies project on building model hydraulic lifts, Jack It Up! Lift a Load Using Hydraulics.

Bibliography

- Wikipedia contributors. (2012, March 25). Crane (machine). Wikipedia: The Free Encyclopedia. Retrieved March 28, 2012.

- Woodford, C. (2007). Hydraulics. Retrieved April 6, 2012.

- Hodanbosi, C. (1996, August). Pascal's principle and hydraulics. National Aeronautics and Space Administration. Retrieved April 6, 2012.

Ask an Expert

Global Connections

The United Nations Sustainable Development Goals (UNSDGs) are a blueprint to achieve a better and more sustainable future for all.

Careers

If you like this project, you might enjoy exploring these related careers: