Abstract

When something goes wrong, do you like to try to figure out why? Engineers do this all the time. They even have a fancy name for it: failure analysis. Understanding how different materials break is an important part of failure analysis. Here's a project with one approach to studying the way things break.Summary

Andrew Olson, Ph.D., Science Buddies

Sources

This project is based on:

- Kelly, T.L., 200 Fractography: The Way Things Break, California State Science Fair Abstract. Retrieved November 15, 2006.

Objective

The goal of this project is to determine if brittle materials break in a similar pattern.

Introduction

Figuring out how things wear out and break is an important part of engineering. There's even a name for it: failure analysis. Failure analysis is a systematic study of how things break. Each different way that a product or structure can fail is called a failure mode. Understanding the different failure modes of materials, products, and structures helps engineers improve their designs, schedule preventive maintenance, and estimate useful lifetime.

One example of failure analysis that you hear about in the news is when the National Transportation Safety Board investigates an airplane crash. There are also more common examples where failure analysis crosses paths with everyday life. Consider, for example, the (usually) simple task of opening a jar to make a peanut butter and jelly sandwich. It happens to be a new jar of jam and, hmmm, the lid seems to be on rather tight. You might run it under hot water, hoping that the metal lid will expand more quickly than the glass threads, helping to free the lid. Or, you might bang the jar lid on the counter, hoping to free it. Hmmm, maybe that wasn't such a good idea.

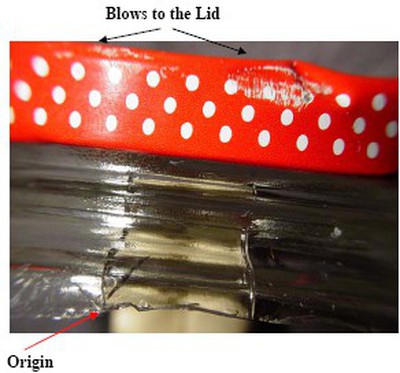

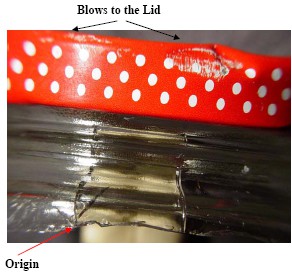

Image Credit: Thomas L. Read, Ph.D. / Copyrighted

Image Credit: Thomas L. Read, Ph.D. / Copyrighted

If you're not careful, it's very easy to hit the neck of the jar on the counter instead of the lid, or to bang the lid to sharply. The glass may develop the beginnings of a crack. As you twist hard on the lid, the strain is released at the crack, and the neck of the jar fails catastrophically, quite possibly leading to a nasty cut on your hand.

Image Credit: Thomas L. Read, Ph.D. / Copyrighted

Image Credit: Thomas L. Read, Ph.D. / Copyrighted

A careful examination of the failed jar shows dents on the jar lid, and the origin of the crack in the glass, just below the dents. It's pretty clear that this jar failed due to the action of the person attempting to open it, not to a manufacturing defect.

In this project, you'll investigate how brittle objects break when subjected to impact forces. Will you find similar failure modes for brittle objects made from different materials?

Terms and Concepts

To do this project, you should do research that enables you to understand the following terms and concepts:

- failure analysis,

- fractography,

- failure mode.

More advanced students may also want to learn about specific failure modes, e.g.:

- ductile overload,

- brittle fracture,

- impact,

- fatigue,

- wear, and

- erosion.

Bibliography

- This website at San Jose State University has an interesting introduction to failure analysis. The page has many interesting links, and discusses both micro- and macro-level fractography:

Pizzo, P.P., 1997. Failure Analysis, Materials Engineering, San Jose State University. Retrieved November 15, 2006. - This site is a good place to start for more information on fractography:

- Parrington, R.J., 2002. "Fractography of Metals and Plastics," Practical Failure Analysis 2(5):16, available online. Retrieved November 15, 2006.

Materials and Equipment

To do this experiment you will need the following materials and equipment:

- leather work gloves,

- eye protection (safety glasses or goggles),

- 5–10 pieces of each material to be tested, e.g.:

- acrylic plastic,

- bathroom tile,

- window glass,

- auto glass;

- metal weight (1–2 kg) to drop on test materials,

- large cardboard box,

- tape measure,

- ruler,

- hand lens (magnifying glass),

- camera (optional).

Experimental Procedure

Safety Note: It is important to wear eye protection when breaking the test materials. Also, be careful when handling the broken pieces, most of which will have sharp edges. Adult supervision is highly recommended.

- Break the test materials by dropping a 1–2 kg metal weight (spherical shape works well) onto the center of the test piece, from a measured height of 1 meter. You may want to place the test material in the bottom of a large cardboard box, to contain the fragments.

- Count and record the number of broken pieces resulting from each test.

- Without disturbing the broken pieces, examine the overall pattern of the resulting fractures. Describe the fracture pattern from the impact. What features are similar and what features are different for each material tested?

- If you have a camera, take photos for further analysis (and for your display board). It will be helpful to have a tripod so that all of your pictures are taken at the same magnfication. Include a ruler in the photo for scale.

- Examine the fracture faces using the magnfiying glass. Compare to photographs from your background research. Are the fractures the same near the impact site and far away from it?

- Summarize your results. How similar were the breakage patterns for different samples of the same material? What similarities (if any) did you find in the breakage patterns of the various test materials? What differences (if any) did you find in the breakage patterns of the various test materials? Can you relate your results to the physical composition of the test materials?

Ask an Expert

Global Connections

The United Nations Sustainable Development Goals (UNSDGs) are a blueprint to achieve a better and more sustainable future for all.

Variations

- What happens if you vary the surface that is supporting the materials when you drop the weight on them?

- In this project, all of the test materials were broken in the same manner, by impact from a solid mass. Can you think of other ways to break the materials? Remember that it is important that your method is reproducible. As one example, you could compare the fractures of materials that were broken by repeated stress with materials broken by impact. Can you identify any features that would allow you to identify how the material was broken?

- In this project, all of the materials were brittle. What happens if you expand the list to include other types of materials, e.g., wood, metals, etc.?

- If you want to take this project even further, you should consider finding a mentor in Materials Science or Materials Engineering. Your mentor may be able to assist you with taking your analysis to the next level by showing you how to perform microscopic analysis of the fractured materials.

Careers

If you like this project, you might enjoy exploring these related careers: