Abstract

If you're interested in arts and crafts, you might like this project. It uses several alternative, renewable sources of fiber to make paper, and compares the resulting papers for strength and writing quality.Summary

- Wear protective clothing and eyewear.

- Use adequate ventilation.

- Always add the soda ash (a strong base) to water, not water to soda ash.

- Use stainless steel or enamel cooking vessel, not aluminum.

Andrew Olson, Ph.D., Science Buddies

Objective

The goal of this project is to make your own paper, test it, and rate its quality, using either recycled paper or plant fibers as the source material.

Introduction

What do you think is the biggest single category of solid waste in the U.S.? Well, since this is a project about paper, that would probably be a good guess. In fact, it's the right answer! According to the U.S. Energy Information Administration, paper and paper products account for 39%, by weight, of the trash we throw away (EIA, date unknown). Newspapers take up 14% of landfill space, and paper products from packaging take up another 15-20% (EIA, date unknown).

Most paper comes from wood pulp (a renewable resource). What other fiber sources can be used to make paper? How can we reduce the amount of paper going to landfills?

In this project you will learn how to make your own paper, using either recycled paper or plant fibers as starting material. You should do background research to learn about the materials that are used in paper, and to find sources of plant fibers that are available locally.

Terms and Concepts

To find more information on this project, try researching the following terms and concepts:

- papermaking,

- lignins,

- cellulose,

- stem fibers,

- leaf fibers,

- bast fibers,

- paper pulp.

Questions

- What part of a plant do "bast fibers" come from?

- What are the primary sources of cellulose fiber for manufacturing paper today?

Bibliography

This website describes how to use recycled paper as the starting material for pulp:

- Mendelow, K, (1999). Handmade Paper. Retrieved September 4, 2012.

This webpages describes making paper pulp from plant materials:

- Lavadour, R. (2004). Papermaking with Plants. Retrieved September 4, 2012.

This resources offers suggestions for suitable plant materials for paper pulp:

- Armstrong, W.P (date unknown). Plant Fibers: Fibers for Paper, Cordage & Textiles. Retrieved September 4, 2012.

This webpage has information on how paper is made (both from pulp and from recycled paper) and how much energy is consumed in the paper-making process:

- United States Energy Information Administration, (date unknown). EIA Kids Page: Recycling. Retrieved September 4, 2012.

Materials and Equipment

- Starting material for making paper pulp:

- Recycled paper

- Plant material: stem fibers, leaf fibers, bast fibers

- Plain gelatin (for "sizing")

- For preparing plant fibers, you will need:

- Rubber gloves to protect your hands. Rubber gloves may be available locally or from online suppliers such as Carolina Biological Supply Company.

- Safety goggles, available from online suppliers such as Carolina Biological Supply Company

- Apron or lab coat, available from online suppliers such as Carolina Biological Supply Company

- Large stainless steel or enamel cooking pot

- Wood ash, or soda ash (sodium carbonate). Sodium carbonate can be purchased through online suppliers such as Carolina Biological Supply Company.

- Net bag to hold pulp while rinsing

- pH strips to test the pH of rinse water. These are available through online suppliers such as Carolina Biological Supply Company

- Blender or wooden mallet for processing fibers after cooking

- For making paper from pulp you will need:

- Mold and deckle, which can be made with:

- 2 5" x 7" picture frames (must have flat faces)

- A 7" x 9" piece of window screen (plastic, not wire screen material is best)

- Staple gun or hammer and tacks

- Large plastic box (dishpan or storage box)

- Stack of absorbent cloths

- Sponge

- Boards to keep paper flat while drying

- Mold and deckle, which can be made with:

Disclaimer: Science Buddies participates in affiliate programs with Home Science Tools, Amazon.com, Carolina Biological, and Jameco Electronics. Proceeds from the affiliate programs help support Science Buddies, a 501(c)(3) public charity, and keep our resources free for everyone. Our top priority is student learning. If you have any comments (positive or negative) related to purchases you've made for science projects from recommendations on our site, please let us know. Write to us at scibuddy@sciencebuddies.org.

Experimental Procedure

The following sections explain the process of making paper by hand. To turn paper-making into a science fair investigation, see the suggestions in the Variations section.

Making Pulp from Recycled Paper

- Cut paper into small pieces, about 2-3 cm on a side.

- Soak the paper pieces in water overnight.

- To make pulp, add a handful of the soaked paper to the blender, and fill about three-quarters full with warm water.

- Blend until your pulp has the consistency of oatmeal (up to one minute). If the blender bogs down, use less paper.

- Pour the mixture into your plastic box. You will probably need to add more water. The pulp should be roughly 90% liquid.

- Repeat blender cycles until you have enough pulp for dipping the mold and deckle.

- Note: this procedure is from Mendelow, 1999.

Making Pulp from Plant Material

- Plant material needs to be cooked in alkaline solution to remove lignins from the cellulose pulp.

- Cut the plant material into small pieces.

- Cut the stems, vines or leaves into 5-7 cm pieces. Process leaves and tougher stems separately.

- Soak plant material in water for 1-2 hours. Rinse.

- Put plant material in large stainless steel or enamel pot filled with cool water.

- Wear proper safety equipment for the rest of the cooking steps: eye protection, rubber gloves, and apron or lab coat.

-

Carefully add soda ash (sodium carbonate) to pot and stir with wooden spoon or stick. To figure the amount of soda ash needed:

- weigh the dry fiber before it is soaked and use 20% of the dry material weight as the amount of soda ash needed; or

- use 1 tablespoon soda ash per 1 qt. water.

- Cook plant material for about three hours. Cool.

- Rinse thoroughly (suspending the cooked plant fibers in a net bag may be useful here). The pH of the pulp should be the same as your tap water (test with litmus paper) when rinsing is complete.

- After cooking, you will need to pound the plant fibers with a mallet and then add water, or blend them (see "Making Pulp from Recycled Paper") to make pulp.

- Note: this procedure is from Lavadour, 2004, and Marks, 2005.

Making a Mold and Deckle

- Use two 5" x 7" picture frames, or make your own wooden frames of similar size. Remove the backing material and glass from the frame; you won't need these, just the wood frame itself.

- Place the plastic window screen material over the face of one of the frames so that it is taut. Fold the material over the sides of the frame and staple or tack it in place.

- The mold is the frame with the screen attached. The other, empty, frame is the deckle.

Making Paper from Pulp

- Pour the pulp into the large plastic box.

- Always stir the pulp immediately before making each sheet of paper.

- With the mold screen-side up, place the deckle on top of the mold. The screen material will be sandwiched in between.

-

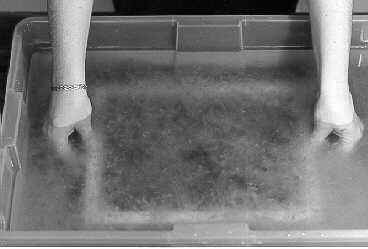

Pick up the mold and deckle together, holding by the short sides, and slide them into the pulp, immersing the mold and deckle completely (Figure 1).

Figure 1. Using the mold and deckle to lift pulp from the plastic box to form a sheet of paper (Lanacaster and Junius, 2002).

Figure 1. Using the mold and deckle to lift pulp from the plastic box to form a sheet of paper (Lanacaster and Junius, 2002).

- Holding the mold and deckle firmly, rock them back and forth gently to distribute the pulp evenly over the screen. Holding the mold and deckle horizontally, slowly lift them out of the pulp. The excess water will drain through the screen.

- Allow the water to drain until it is no longer dripping. This may take as long as two minutes. You may want to (carefully!) set the mold and deckle across the corner of your plastic box while it drains.

-

When the excess water has drained, set the mold and deckle down on a flat surface and carefully remove the deckle, starting at one corner. The paper should remain attached to the screen surface of the mold (Figure 2).

Figure 2. Lifting the deckle from the mold (Lanacaster and Junius, 2002).

Figure 2. Lifting the deckle from the mold (Lanacaster and Junius, 2002).

-

The next step is called "couching." You need to flip the mold over, paper side down, onto the couching cloth, which will absorb more water from the paper. You can use felt, handiwipes, cut pieces from old sheets-practically any clean, absorbent cloth will do. Use a sponge to remove excess water through the screen material of the mold (Figure 3). You can squeeze the water out of the sponge into another container or back into the plastic box with the pulp.

Figure 3. Couching the sheet of paper on absorbent cloth. Use a sponge to carefully remove excess water from the back side of the screen (Lancaster and Junius, 2002).

Figure 3. Couching the sheet of paper on absorbent cloth. Use a sponge to carefully remove excess water from the back side of the screen (Lancaster and Junius, 2002).

-

When the paper begins to separate from the screen, you can carefully lift the mold away from the couching material. Start at one corner of the mold, and make sure that the paper separates cleanly and remains flat on the cloth (Figure 4).

Image Credit: Lancaster and Junius, 2002, UCSD

Figure 4. Lifting the mold to reveal your brand-new sheet of paper (Lancaster and Junius, 2002).

Image Credit: Lancaster and Junius, 2002, UCSD

Figure 4. Lifting the mold to reveal your brand-new sheet of paper (Lancaster and Junius, 2002).

- The finished paper needs to be dried between boards for several days, with weight on top to keep it from curling. Keep layers of cloth between the sheets of paper to permit drying. You can speed the drying process by ironing the paper between sheets of cloth. The paper should still be weighted after drying to keep it flat.

-

Rate the quality of your paper for different tasks, for example:

- writing with pencil,

- writing with pen,

- painting,

- or perhaps even making model airplanes, or origami!

Ask an Expert

Global Connections

The United Nations Sustainable Development Goals (UNSDGs) are a blueprint to achieve a better and more sustainable future for all.

Variations

- For making paper with recycled paper as a starting material: do you get better results with newspaper or office paper as starting material? What happens if you use glossy paper from magazines?

- Compare the quality of the paper produced from fibers from different types of plants.

- "Sizing" is material such as gelatin that is added to the paper pulp when the paper is to be used for writing or calligraphy. What does sizing do for the paper? Make several sheets of paper with and without sizing. Keep the sheets in separate, labeled stacks as they are drying so that you know which is which, and label the sheets when they are dry. Test the papers for suitability for writing with pencil, ballpoint pen, and fountain pen. How do the two papers work for watercolor painting?

- Compare the resources used to make paper with recycled paper as the starting point vs. raw plant material. How much is the savings in materials and energy? How does this compare to industrial paper processing from recycled materials vs. wood pulp? What percentage of the paper goods used in your household gets recycled? How about your neighborhood, your school, or local businesses? What can you do to increase the percentage?

- Advanced. Do background research on the growth rates of different types of plants used for paper pulp: e.g., jack pine and aspen. How do these compare to the plants that you used to make paper?

- Advanced. Are there alternative methods to alkali treatment for removing the lignins from raw plant materials? Are these methods more environmentally friendly? Design an experiment to find out.

Careers

If you like this project, you might enjoy exploring these related careers:

Related Links

- Science Fair Project Guide

- Other Ideas Like This

- Environmental Engineering Project Ideas

- My Favorites