Lift a Load using Liquids

Summary

Introduction

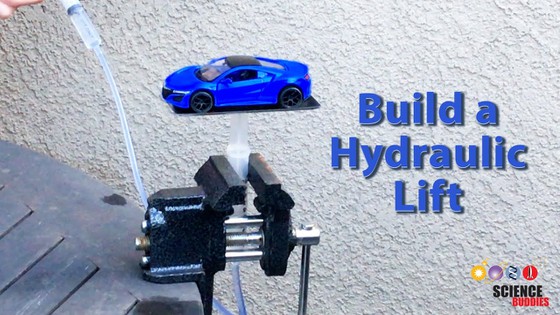

No one, not even a very strong human, is strong enough to lift a truck. However, our brains are smart enough to create a tool that can lift heavy objects for us: hydraulic lifts! You find them in body shops, on skyscraper construction sites, in wheelchair lifts, and in dentist chairs, and you will even build one in this activity! Try it out and discover how much more you can lift.

Background

If you have ever used a wheelbarrow, you know it can help you lift heavy objects; lifting the handles of the wheelbarrow is easier than lifting the object itself. A hydraulic lift does the same; it allows you to move a heavy object with very little effort.

The term “hydraulics” refers to tools that operate by using moving liquids like water or oil. It uses a liquid and not, for example, air – which is a gas - because liquids are incompressible. This means that no matter how hard you press on a liquid, you cannot noticeably change its volume. Try it out! Fill a syringe with water, close its tip with a finger, and try to press the piston in. You will see that you cannot; even placing an elephant (if you were able to) on the piston would not compress the fluid in the syringe. But, what would happen when a tube filled with water connects the tip of this syringe to the tip of a second syringe? That is exactly what you will try in this activity!

In the effort to move something, it is not only important to push hard; the area over which the push is spread out can be important too. Think of a time when you played with playdough. Pushing a finger into the dough is easy, but pushing the palm of your hand into the dough is much harder. Because your hand has a larger surface area, your effort is spread out over a larger area and the playdough does not feel as much pressure. Is there a way to place your heavy object on a large surface so it creates less pressure? Do the activity to find out!

Materials

- Two stainless steel wall plates, at least 4.5 x 2.75 in size. These are available in any hardware store.

- Two small and one large syringe. The combination of 25 cc and 60 cc syringes works well. Look for syringes with a catheter tip as these tips can easily be connected with a plastic pipe.

- Epoxy glue, paper plate, and disposable spoon or extra-strong wall-mount double-sided tape

- Two feet of silicone fuel tubing, with a 5/32-inch inner diameter. This is available in a hobby shop, a hardware store, or online.

- Vise

- Mason jars, water jug, or other heavy weights

- Water

- Ruler

- Adult volunteer

- Plumber's putty (optional)

- Scale (optional)

- Other sizes of syringes with catheter tip (optional)

- Oil (optional)

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Preparation

- Put one small syringe away to the side. This syringe will be the primary syringe; you will use it to make the lift move. The other two syringes will hold the object that needs to be lifted. These are called secondary syringes.

- Ask an adult to help you glue the wall plates to the flat top of the pistons on the two secondary syringes (one small and one large syringe). Aim to glue the pistons to the center of the plates. Use epoxy glue or, if unavailable, very strong adhesive tape. Let the glue fully dry before starting the activity.

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

- For The primary syringe (the syringe without plate attached):

- Push the piston in the syringe all the way down so that it is fully depressed into the cylinder.

- Submerse the tip of the syringe in water and pull the piston back as far as it can go. The syringe will suck up water.

- Connect a plastic tube to the tip of this syringe.

- Hold the syringe with its tip pointing up. Remove the air bubble near the tip of the syringe and the air in the tube by pushing the piston in until all the air is pushed out of the tube.

- Put the free end of the tube in water and pull the piston smoothly up as far as it can go without falling out of the syringe. The syringe will suck up water.

- At the end of this procedure, very little air should be left in the tube and the syringe. The syringe should be full.

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

- Attach the vise to a sturdy surface.

Instructions

- Insert the tip of the smallest secondary syringe into the free end of the tube connected to the primary syringe. Push the piston of this primary syringe in. What happens to the secondary syringe? Why would this happen? Do you need to push hard to get the liquid to transfer from one syringe to the other?

- Note: If the tubing pops off, refill the tube and primary syringe with water, and reattach the tube to the secondary syringe. If needed, seal the connection with plumber's putty.

- Transfer the liquid back to the primary syringe by pushing the piston of the secondary syringe down until the primary syringe is filled with liquid.

- Use the vise to mount the secondary syringe vertically with the plate horizontal and facing up. Do not squish the cylinder of the syringe as this will obstruct the movement of the piston.

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

- Fill the mason jar with water and place it in the center of the platform attached to the secondary syringe in the vise. Do you think you can easily lift this weight by pushing on the primary syringe's piston?

- Try it out. Push gently so the jar does not tumble off. You might need a helper to gently keep the construction upright. Was your prediction correct?

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

- If you can lift this weight with ease, take the jar of the platform, push the piston of the secondary syringe down until the primary syringe is filled with liquid, and then place two jars (or another heavier weight) on the platform and try again. Repeat this step until you feel it is hard to lift the weight mounted on the platform.

- As you are repeating this step, notice how high your load (the jar with water) is moving. Write this distance down.

- Once you find the amount, write down what you had on the plate as weights. If you have a scale available, weigh the largest weight that you are still able to lift.

- You just tested a design in which the primary and secondary syringes are equal in size. Switch the secondary syringe (the syringe that holds the weights) to one that is larger than the primary syringe. Do you think you will be able to lift more weight, less weight, or about the same weight with this design? Do you think the jar will move up more, less, or about the same? Why do you think this?

- Repeat the procedure with the larger secondary syringe to find out!

- Compare the measurements you made in both designs. Why do you think they are different? Which design would you choose to lift a heavy truck, and why?

- EXTRA: Try other combinations of syringe sizes. Can you see a pattern in your findings?

- EXTRA: This activity uses water as the liquid in the syringe system. Test a system filled with oil. How does this change affect the lift?

- EXTRA: Measure the radius of both the small and large secondary syringe cylinders. Can you use these numbers to find the factor by which the weight you can lift gets multiplied when you move from a small to a large syringe? Or can you use these numbers to find the factor by which the load’s movement is reduced?

- EXTRA: Make a hydraulically operated wheelchair lift, dental office chair, or car lift for your toys.

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Observations and Results

You were probably able to lift much more weight with the large secondary syringe compared to the small secondary syringe, and the jar probably moved over a much shorter distance. That is exactly what happens in a hydraulic lift when the secondary piston is larger than the primary piston.

When you press one piston, the liquid inside the closed system feels the pressure, and it presses with an equal amount against the other piston. Because pressure is created by applying force over an area, a small push on a small area creates the same pressure as a much larger push on a much larger area. That is why a hydraulic lift can multiply a force: you push on a small piston, the pressure that is created moves through the liquid to a much larger piston, and the load on the larger piston feels a much larger push than the one you first made. For the same reason, you could move more weight with a large secondary syringe compared to a smaller one.

Did you see how liquid was transferred from one column to the other in the process? Because the volume of liquid does not change, the larger piston will not move as much as the smaller piston, but that is a small price to pay to be able to lift a heavy object.

Image Credit: Sabine De Brabandere, Science Buddies / Science Buddies

Image Credit: Sabine De Brabandere, Science Buddies / Science BuddiesOn the left, a hydraulic lift where the secondary syringe is much wider than the primary syringe. A large toy truck is on the platform. The secondary piston does not stick out by much while the primary piston is fully pushed in. On the right, a similar hydraulic lift where the secondary syringe is much narrower. A toy car is on the platform. The secondary piston stick out completely lifting the car over a large distance.

Ask an Expert

Additional Resources

Jack It Up! Lift a Load Using Hydraulics, by Science Buddies

The multiplication of force by a hydraulic system, by Wisc Online

Dam Design, Scientific American

Science Activities for All Ages!, from Science Buddies