Wire Stripping Tutorial

Introduction

There are two types of electrical wire that you will commonly encounter in Science Buddies projects: hookup wire and magnet wire. Hookup wire and magnet wire both come in different sizes, measured on a scale called wire gauge. Both types of wire are covered in insulation, which is material that does not conduct electricity. In order to use either type of wire in your science projects, you typically must remove small amounts of insulation from the ends. This tutorial will give you a brief introduction to both types of wire, and how to remove (or "strip") the insulation. You can click through the grey tabs above to learn more about each type, or use the links below to jump right to the section you need.

- About Wire Gauge

- What Is Hookup Wire?

- Stripping Hookup Wire

- What Is Magnet Wire?

- Stripping Magnet Wire

About Wire Gage

Wire "gauge" is a scale used to measure the diameter of a wire. There are different wire gauge scales, but the most common one you will hear about is American Wire Gauge, abbreviated AWG. Most Science Buddies projects will tell you exactly what kind of wire you need to buy, so you do not need to worry about the details of the system, or its origins. There are two important things you should understand:

- As the wire gauge number gets bigger, the diameter gets smaller. This is counterintuitive and takes some getting used to. For example, 30 AWG wire has a smaller diameter than 12 AWG wire.

- The AWG value does not include the wire's insulation. AWG only measures the diameter of the metal part of the wire.

Using Hookup Wire

About Hookup Wire

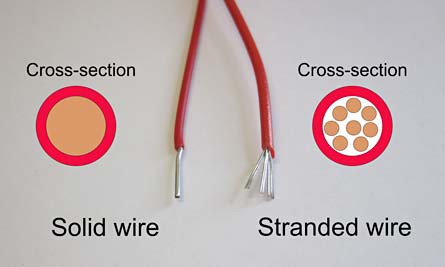

Hookup wire has relatively thick, opaque (can not be seen through) rubber or plastic insulation, and is frequently used when building circuits or robots, or when using solderless breadboards. There are two different kinds of hookup wire: solid wire and stranded wire. Solid wire has a single solid "core" made out of conductive metal (usually copper, or a mix of copper and another metal called an alloy); it is stronger, but it is not as flexible as stranded wire. It is usually used when you have to push one end of the wire into a breadboard. Stranded wire is made up of multiple strands of individual wires, which makes it more flexible, but also makes it very difficult to push the ends into a breadboard. Figure 1 shows a close-up of the difference between solid wire and stranded wire:

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Figure 1. Solid wire (left) has a single solid core made out of conductive metal. It is generally stiffer and less flexible, so bending the wire repeatedly or very sharply can cause it to break. Stranded wire (right) is made up of many individual strands of smaller wires, and is much more flexible but not as stiff, so cannot easily be used with breadboards.

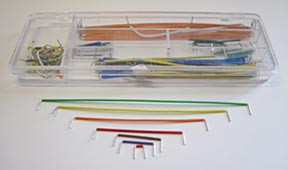

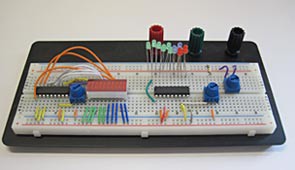

Hookup wire can usually be purchased in two forms: spools or jumper wire kits (Figure 2). Spools provide one continuous segment of wire that you must cut and strip yourself. Jumper wire kits contain many pre-cut short pieces of solid-core wire, with ends that are bent down 90 degrees and already have the insulation removed. This makes them perfect for working with solderless breadboards.

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Figure 2. Hookup wire is available in spools with many different colors of insulation (left), and in kits with pre-cut lengths (center), which can help with color-coding complicated circuits, like on this breadboard (right).

The American Wire Gauge system actually measures the total cross-sectional area of the metal in a wire. For a solid-core wire, the cross-sectional area is directly related to the wire diameter, since the cross section is just a circle (through the equation A = πr², where r is the circle's radius, or one-half of the diameter). The cross section of stranded wire is made up of many smaller circles with empty space in between them (refer to Figure 1, above), and the AWG system only counts the area of the metal circles, and not the empty space. This means that if a stranded wire and a solid wire have the same wire gauge (meaning, they have the same total cross-sectional area of metal), the stranded wire will actually have a slightly bigger total diameter, because of the air gaps in between the individual strands of wire.

For example, imagine a solid-core wire with a cross-sectional area of 10 mm². Now imagine ten smaller wires with cross-sectional areas of 1 mm² each. No matter how tightly you bundle those ten smaller wires together, there will always be some space in between them, meaning the total outer diameter of your bundle of wires will be slightly larger than the single solid wire.

Many wire strippers have separate gauges for solid and stranded wire to account for this difference.

Stripping Hookup Wire

The easiest way to strip hookup wire is to use a pair of wire strippers. Wire strippers are not very expensive (you can get a good pair for under $10) and can be a great investment if you plan on doing more electronics projects in the future. They are available at hardware stores, electronics stores like RadioShack, and online retailers like Jameco.com and Amazon.com. If you do not want to spend the money on wire strippers, or your science project is due tomorrow and you do not have time to buy a pair, you can also use a sharp knife (with adult supervision), or even a pair of nail clippers. The following video demonstrates how to strip insulation from hookup wire using three different types of wire strippers or a hobby knife:

Using Magnet Wire

About Magnet Wire

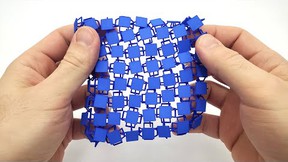

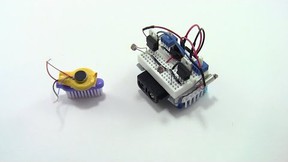

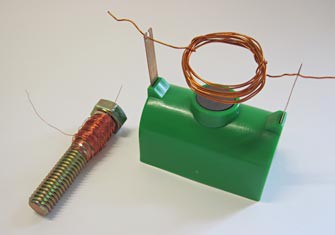

Magnet wire has relatively thin enamel coating (so it is also called "enamel-coated wire"), and it is frequently used to make electromagnets, solenoids or electrical motors. Figure 3 shows several spools of magnet wire and two example uses.

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Image Credit: Ben Finio, Science Buddies / Science Buddies

Figure 3. (Left) Spools of magnet wire. The enamel coating is usually translucent, but can still come in different colors. (Right) Two, of many, possible applications for magnet wire: wrapping it around a bolt to create an electromagnet, and building a toy motor.

Stripping Magnet Wire

The easiest way to strip the enamel insulation off of magnet wire is to use an abrasive surface like sandpaper. If sandpaper is not available, other solutions like pinching the wire between two nail files will also work. The following video demonstrates how to strip magnet wire: